Added Services

Added services to your product will increase your product’s value and make it stand out from the competition, whether it is coating, foil stamping, embossing or debossing.

Coating

Print coatings are used on custom boxes primarily for protection or to achieve certain visual effects. Coatings can provide protection from moisture, scuffing, scratching and finger prints. They can also be applied to one or both sides of a printed piece to create a glossy or dull finish or can be applied selectively (spot coating) to highlight a certain visual element. Choices of coatings include aqueous, soft touch, UV, Pearlescent, and UV Glitter.

Aqueous: Aqueous coating is a clear, fast-drying water-based coating that is used to protect printed pieces. It provides a high-gloss, satin, or matte surface that deters dirt and fingerprints. Aqueous coatings provide substantial rub and scuff-resistance. Due to its water base, aqueous coating is more environmentally friendly than UV coatings.

Soft Touch: Soft Touch creates a velvety texture. The paper becomes “soft” to the touch and increases the tactile appeal. It creates a softer look and feel on printed materials than either aqueous or UV coating, while creating a barrier which is fingerprint resistant. It dries fast, is non-yellowing, and is eco-friendly.

UV: UV coatings provide the highest gloss versus other coatings. Some find it too shiny for some uses. UV coatings can be applied as a flood (covering the entire printed sheet) or as a spot coating. UV compatible inks must be used on sheets that will be UV coated.

Pearlescent: A pearlescent coating can enrich custom boxes with an elegant surface and unique visual effects, produces a shimmering, reflective effect. It adds texture to custom boxes in a way that is subtle and lush. A pearlescent coating may be applied to the entire surface of the box or to a spot area. Pearlescent coatings are often used for custom cosmetic boxes, but they may also be used for a variety of products, including holiday items, custom candy boxes such as chocolate, and many others.

UV Glitter: UV Glitter can add a unique value for customers who want special effects that sparkle and is available in various colors and cut sizes. It may be applied to the entire surface of the box or to a spot area and is often used to highlight and attract attention to details on custom boxes, especially when used against a light colored background.

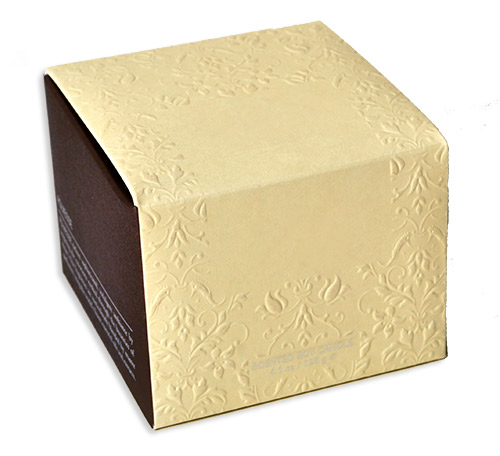

Embossing

Foil

Foil and Spot UV

Spot UV

Foil Stamping

Foil stamping uses heat and metallic film in a specialty printing process that produces a shiny design on paper. With foil stamping, you can achieve a brilliance that cannot be duplicated with ink. A wide spectrum of matte, gloss, metallic, or holographic foils are available in various colors. Foil stamping can be combined with embossing to yield a pattern of foil embossings on custom printed boxes or unprinted custom boxes.

Embossing / Debossing

Contact us to discuss your requirements for any added services for custom boxes or Request a Quote for your next custom packaging boxes. Thinking outside the box about boxes… that’s Imperial Printing & Paper Box Mfg. Co.